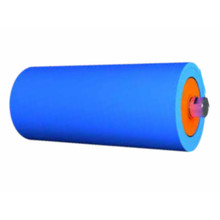

Conveyor System/Conveyor Belt/Pipe Conveyor Belt

Basic Info

Model No.: NN 400

Product Description

Model NO.: NN 400 Material: Rubber Feature: Oil-Resistant, Acid And Alkali Resistant, Tear-Resistant, Heat-Resistant, Cold-Resistant, Wear-Resistant Width: 400 mm ~ 2000 mm Thickness of Bottom Rubber: 1.5 mm ~ 4.0 mm Abrasion Loss: 90 mm3 ~ 200 mm3 Color: Black Model Number: GB, DIN, as, Cema, ASTM, Ash Trademark: OUNA Origin: Anhui, China Type: NN400 Inside Material: Nylon Tensile Strength: Strong Thickness of Top Rubber: 3.0 mm ~ 8.0 mm Elongation at Break: 350% ~ 400% Strength: 100 N/mm ~ 4000 N/mm Certificate: ISO 9001 Place of Origin: Anhui, China Specification: ISO, DIN, AS, GB, CEMA, ASTM, SHA HS Code: 4010110000 Construction:

Pipe Conveyor Belt takes high-strength canvas or steel cable as its carcass in combination with high-strength high abrasion-resistance high-quality rubber as the top and bottom rubber cover, during the operation.

Features:

(1) Pipe belt itself has appropriate transverse rigidness, which can ensure good retention and seal of tubular shape.

(2) The belt body has good elasticity and longitudinal flexibility, making the belt able to tolerate repeated and long-time violent bending and shrinkage;

(3) The belt has excellent physical and mechanical properties. It is required that the outer cover rubber has higher resistance to weather, ozone, ultraviolet rays, flexure, cracking etc., while inner cover rubber should have excellent abrasion resistance.

(4) Because of special structure of Tubular Belt, it conveys powdery material in tubular closed condition during the conveying, thus it can effectively prevent dust fly and spill.

(5) By adopting Tubular Conveyor Belt for conveying, the material is wrapped in the rubber belt, this increasing the area of contact between material and rubber belt and internal friction angle of material, thus can increase the inclination angle of material conveying of the conveyor.

(6) With tubular belt adopted for conveying, after the belt presents tubular shape, it can run horizontally, vertically or curvilinearly, the conveying line can be arranged according to the space within a certain range without setting intermediate transfer station, therefore, construction investment can be saved.

(7) Tubular belt conveying avoids bias with reliable running, improved conveying efficiency and better economic benefit and lower running cost.

(8) With tubular belt for conveying material, the return run after discharge can also convey material, i.e. two-way conveying. This can not be achieved with ordinary Conveyor Belt.

Application:

It is widely applied in enclosed conveying of bulk materials in the sectors as of metallurgy, electric power, chemical engineering, harbor, wharf, building materials, coal, mine, grains etc. It has multiple types such as abrasion-resistant, heat-resistant, cold-resistant, corrosion-resistant, flame-resistant, antistatic etc.

Specification series

Marking of pipe belt with textile carcass

Marking of steel cord pipe belt

Specifications and technical parameters of Tubular Conveyor belt with nylon canvas carcass

Recommended min. roller diameter of conveyor (Pipe Conveyor belt with nylon canvas carcass)

Specification parameters of steel wire tubular conveyor belt

Recommended min. roller diameter of conveyor (steel cord pipe conveyor belt)

Contact us if you need more details on Pipe Conveyor Belt. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Belt、Conveyor Belt. If these products fail to match your need, please contact us and we would like to provide relevant information.

Pipe Conveyor Belt takes high-strength canvas or steel cable as its carcass in combination with high-strength high abrasion-resistance high-quality rubber as the top and bottom rubber cover, during the operation.

Features:

(1) Pipe belt itself has appropriate transverse rigidness, which can ensure good retention and seal of tubular shape.

(2) The belt body has good elasticity and longitudinal flexibility, making the belt able to tolerate repeated and long-time violent bending and shrinkage;

(3) The belt has excellent physical and mechanical properties. It is required that the outer cover rubber has higher resistance to weather, ozone, ultraviolet rays, flexure, cracking etc., while inner cover rubber should have excellent abrasion resistance.

(4) Because of special structure of Tubular Belt, it conveys powdery material in tubular closed condition during the conveying, thus it can effectively prevent dust fly and spill.

(5) By adopting Tubular Conveyor Belt for conveying, the material is wrapped in the rubber belt, this increasing the area of contact between material and rubber belt and internal friction angle of material, thus can increase the inclination angle of material conveying of the conveyor.

(6) With tubular belt adopted for conveying, after the belt presents tubular shape, it can run horizontally, vertically or curvilinearly, the conveying line can be arranged according to the space within a certain range without setting intermediate transfer station, therefore, construction investment can be saved.

(7) Tubular belt conveying avoids bias with reliable running, improved conveying efficiency and better economic benefit and lower running cost.

(8) With tubular belt for conveying material, the return run after discharge can also convey material, i.e. two-way conveying. This can not be achieved with ordinary Conveyor Belt.

Application:

It is widely applied in enclosed conveying of bulk materials in the sectors as of metallurgy, electric power, chemical engineering, harbor, wharf, building materials, coal, mine, grains etc. It has multiple types such as abrasion-resistant, heat-resistant, cold-resistant, corrosion-resistant, flame-resistant, antistatic etc.

Specification series

| (mm) Tube diameter | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 700 |

| (mm) Belt width | 360 | 600 | 800 | 1000 | 1100 | 1300 | 1600 | 1850 | 2250 | 2450 |

| (m2) Sectional area | 0.008 | 0.018 | 0.031 | 0.053 | 0.064 | 0.09 | 1.147 | 0.21 | 0.291 | 0.379 |

| (mm) Max lump size | 30 | 30-50 | 50-70 | 70-90 | 90-100 | 100-120 | 120-150 | 150-200 | 200-250 | 250-300 |

Marking of pipe belt with textile carcass

| 100 | 1000 | NN | 4 | 800 | 4+2+2 | 18 |

| Length (m) | Width (mm) | Carcass material | Number of belt cord plies | Longitudinal tensile strength over full thickness (mm) | Thickness of top and bottom rubber cover and transition layer (mm) | Performance of cover (MPa) |

Marking of steel cord pipe belt

| 1000 | ST | 800 | 5+5 | M |

| Width (mm) | Material code of belt cord | Longitudinal tensile strength over full thickness | Thickness of top and bottom rubber cover (mm) | Grade code of cover performance |

Specifications and technical parameters of Tubular Conveyor belt with nylon canvas carcass

| mm Tube diameter | mm Width | N/mm Tear strength | Number of fabric plies | Model of Fabric | ×mmThickness of cover rubber Inner × outer | mm Total thickness |

| 100 | 430 | 250 | 1 | NN-300 | 3.0x1.5 | 5.2 |

| 150 | 600 | 160 | 2 | NN-100 | 3.0x2.0 | 7.5 |

| 315 | NN-200 | |||||

| 200 | 750 | 315 | 2 | NN-200 | 3.0x2.0 | 7.9 |

| 500 | NN-300 | |||||

| 315 | NN-200 | 5.0x2.0 | 9.4 | |||

| 500 | NN-300 | 8.9 | ||||

| 250 | 1000 | 400 | 2 | NN-250 | 3.0x2.0 | 8.6 |

| 500 | NN-300 | 9 | ||||

| 400 | NN-250 | 5.0x2.0 | 10.1 | |||

| 500 | NN-300 | 10.4 | ||||

| 300 | 1100 | 400 | 2 | NN-250 | 3.0x2.0 | 9.1 |

| 500 | NN-300 | 9.5 | ||||

| 400 | NN-250 | 5.0x2.0 | 10.6 | |||

| 500 | NN-300 | 11 | ||||

| 350 | 1300 | 630 | 3 | NN-250 | 5.0x2.0 | 11.9 |

| 800 | 4 | NN-300 | 12.5 | |||

| 400 | 1600 | 800 | 4 | NN-250 | 5.0x2.0 | 13.1 |

| 1000 | 5 | NN-300 | 13.9 |

Recommended min. roller diameter of conveyor (Pipe Conveyor belt with nylon canvas carcass)

| Number of plies Roller diameter Model | 2 | 3 | 4 | 5 |

| NN-100 | 200 | 250 | 315 | 400 |

| NN-200 | 250 | 315 | 400 | 500 |

| NN-250 | 315 | 400 | 500 | 630 |

| NN-300 | 400 | 500 | 600 | 800 |

Specification parameters of steel wire tubular conveyor belt

| Item Strength specification | St 630 | St 800 | St 1000 | St 1250 | St 1600 | St 2000 | St 2500 | St 2800 | St 3150 | St 3500 | St 4000 | St 4500 | St 5000 | St 5400 | |

| N/mm Longitudinal tensile strength | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 2800 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 | |

| mm Max. nominal diameter of steel cable (mm) | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 6.0 | 7.5 | 7.6 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 | |

| ±1.5mm Space between steel cables | 10 | 10 | 12 | 12 | 12 | 12 | 15 | 15 | 15 | 15 | 15 | 16 | 17 | 17 | |

| mm Thickness of top rubber cover | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 10 | 10 | |

| mm Thickness of bottom rubber cover | 5 | 5 | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | |

| mm Thickness of intermediate layer for rigidness adjustment | Transverse rigidness value is provided by the customer, and our company prepare the corresponding intermediate rigidness adjustment layer according to his need, the thickness of adjusting layer is 3~6mm. | ||||||||||||||

| mm Tube diameter | mm Width | Number of steel cables | |||||||||||||

| 200 | 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | 50 | 50 | -- | -- | -- | -- |

| 250 | 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64 | 64 | 59 | 55 | 55 |

| 300 | 1100 | 105 | 105 | 87 | 87 | 87 | 87 | 69 | 69 | 69 | 69 | 69 | 65 | 61 | 61 |

| 350 | 1300 | 124 | 124 | 103 | 103 | 103 | 103 | 83 | 83 | 83 | 83 | 83 | 77 | 72 | 72 |

| 400 | 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 101 | 101 | 101 | 101 | 96 | 90 | 90 |

| 500 | 1850 | 177 | 177 | 147 | 147 | 147 | 147 | 119 | 119 | 119 | 119 | 119 | 111 | 104 | 104 |

| 600 | 2250 | -- | -- | 181 | 181 | 181 | 181 | 145 | 145 | 145 | 145 | 145 | 137 | 125 | 125 |

| 700 | 2450 | -- | -- | 197 | 197 | 197 | 197 | 158 | 158 | 158 | 158 | 158 | 148 | 139 | 139 |

Recommended min. roller diameter of conveyor (steel cord pipe conveyor belt)

| Type of belt | St 630 | St 800 | St 1000 | St 1250 | St 1600 | St 2000 | St 2500 | St 2800 | St 3150 | St 3500 | St 4000 | St 4500 | St 5000 | St 5400 |

| mm Min. roller diameter | 500 | 630 | 630 | 800 | 800 | 1000 | 1250 | 1250 | 1250 | 1250 | 1400 | 1600 | 1600 | 1800 |

Contact us if you need more details on Pipe Conveyor Belt. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Belt、Conveyor Belt. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Conveyor Belt > Nylon Conveyor Belt

Premium Related Products

Other Products

Hot Products

Ep300/3 Drive Belt Rubber Conveyor BeltInterlocking Dog Bone Rubber Flooring, Rubber Paving TilesHot Sale! ! Impact Resistant SBR Rubber Sheet with Fabric InsertionLarge Capacity Chevron Rubber Conveyor Belt Made in ChinaEp/Nn/Cc Conveyor Belt From FactoryFirst Class Anti-Tear Conveyor BeltsEPDM Foaming Strip for Doors & Windows SealingMine, Stone, Sand Cement Fabric Nylon Nn Ep Cc56 Tc70 Steel Cord Black Rubber Conveyor Belt / Belt ConveyorTransmission Belt of Oil-Resistant Conveyor BeltRubber Belt of Impact-Resistant Conveyor Belt for Large Goods TransportaionConveyor Blet / Non-Stick Conveyor BeltPipe Conveyor Belt for Coal MiningWear-Resistant (Transmission) Chervon BeltHeat-Resistant Conveyor Belt for Gas WorksProfessional Sidewall Rubber Conveyor Belt/ Transmission Rubber Conveyor BeltNylon Rubber Conveyor Belt / Transmission Belt Made in China