Cema/DIN/ASTM/Sha Standard Anti-Slip Chevron Pattern Conveyor Belt/Pattern Conveyor Belt

Basic Info

Model No.: CB70

Product Description

Model NO.: CB70 Material: Rubber Feature: Oil-Resistant, Acid And Alkali Resistant, Tear-Resistant, Heat-Resistant, Cold-Resistant, Wear-Resistant Performance Indexes: GB/T7984 No.of Ply: 3-10 Plies Advantage 2: Good Flexibility & Good Troughability Trademark: OUNA Origin: Toncheng, China Type: Ep100-Ep500 Inside Material: Cotton Tensile Strength: Strong Applications: Mining/ Metallurgy/Cement/Harbor etc. Advantage1: Fatigue Resistance Standards: Cema,ASTM,DIN,Sha.etc Specification: ISO9001: 2008 HS Code: 40101900 CEMA/DIN/ASTM/SHA Standard anti-slip chevron pattern Conveyor Belt/pattern conveyor belt prevent materials from falling down

Features:

Pattern conveyor belt is the one where inclination angle is formed between the working surface (the patterned cover rubber) and non-working surface (planar cover rubber) and the belt carcass.

Application:

It can convey powdered, granulated and small lump materials at the gradient of no more than 60°, it can also convey packaged materials in order to preventing downslide of materials.

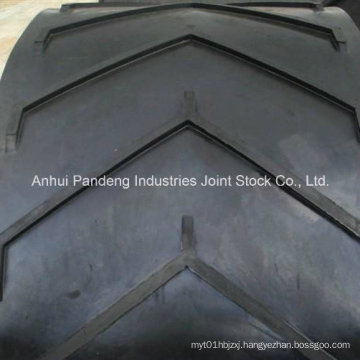

Chevron pattern

Feature: there is "chevron" pattern higher than the belt body on the belt surface, the pattern can be open type or closed, each kind of pattern can further be divided into three kinds-high, medium and low.

Application: suitable conveying of powdery, granular and small-lump material at inclination angle of ≤40° or conveying of bagged material.

Strip pattern

Feature: there is strip pattern higher than belt body on the belt body in transverse direction, the pattern is divided into three kinds-high, medium and low, each pattern can further be divided into loose and dense etc. according the placing space.

Application: suitable for horizontal conveying of packages at inclination angle of ≤30°. In case of trough, it can substitute chevron-shaped pattern.

Grainy pattern

Feature: there is grainy pattern higher than the belt body or recessed in the belt body on the belt surface, the recesses can also be made into square hole, or prismatic and cloth grain lines.

Application: raised grainy pattern is suitable for conveying of soft packages or material needing holding power (e.g. carton) or slipless conveying.

Recessed grainy pattern is suitable for conveying granular material at inclination angle of ≤45°.

Segmental pattern

Feature: there is half-sector (or 1/4 circle) pattern on the belt surface. When the rubber belt is troughed, the pattern is closed into a sector (or half-circle), it is of embossed pattern.

Application: suitable for conveying powdery, granular and lumpy material at large inclination angle of ≤60°. Suitable for conveying materials at relatively large inclination angle. It is widely used in the fields of coal, mining, electric power, metallurgy, chemical engineering, light industry, grains, etc. for material conveying.

Performance indexes(GB/T7984)

Performance of cover

Note: The elongation of reference force in longitudinal direction over the full thickness of the belt is not greater than 4%.

Ply bond strength

Recommended min. diameter of roller

Contact us if you need more details on Chevron Conveyor Belt. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pattern Conveyor Belt、Cotton Conveyor Belt. If these products fail to match your need, please contact us and we would like to provide relevant information.

Features:

Pattern conveyor belt is the one where inclination angle is formed between the working surface (the patterned cover rubber) and non-working surface (planar cover rubber) and the belt carcass.

Application:

It can convey powdered, granulated and small lump materials at the gradient of no more than 60°, it can also convey packaged materials in order to preventing downslide of materials.

Chevron pattern

Feature: there is "chevron" pattern higher than the belt body on the belt surface, the pattern can be open type or closed, each kind of pattern can further be divided into three kinds-high, medium and low.

Application: suitable conveying of powdery, granular and small-lump material at inclination angle of ≤40° or conveying of bagged material.

Strip pattern

Feature: there is strip pattern higher than belt body on the belt body in transverse direction, the pattern is divided into three kinds-high, medium and low, each pattern can further be divided into loose and dense etc. according the placing space.

Application: suitable for horizontal conveying of packages at inclination angle of ≤30°. In case of trough, it can substitute chevron-shaped pattern.

Grainy pattern

Feature: there is grainy pattern higher than the belt body or recessed in the belt body on the belt surface, the recesses can also be made into square hole, or prismatic and cloth grain lines.

Application: raised grainy pattern is suitable for conveying of soft packages or material needing holding power (e.g. carton) or slipless conveying.

Recessed grainy pattern is suitable for conveying granular material at inclination angle of ≤45°.

Segmental pattern

Feature: there is half-sector (or 1/4 circle) pattern on the belt surface. When the rubber belt is troughed, the pattern is closed into a sector (or half-circle), it is of embossed pattern.

Application: suitable for conveying powdery, granular and lumpy material at large inclination angle of ≤60°. Suitable for conveying materials at relatively large inclination angle. It is widely used in the fields of coal, mining, electric power, metallurgy, chemical engineering, light industry, grains, etc. for material conveying.

Performance indexes(GB/T7984)

Performance of cover

| Performance of rubber cover | Tensile strength | H | MPa | ≥24 |

| D | MPa | ≥18 | ||

| L | MPa | ≥15 | ||

| Elongation at break | H | % | ≥450 | |

| D | % | ≥400 | ||

| L | % | ≥350 | ||

| Abrasion loss | H | mm3 | ≤120 | |

| D | mm3 | ≤100 | ||

| L | mm3 | ≤200 | ||

| Thickness of rubber cover | The thickness of common top and bottom rubber cover is 3.0+1.5mm, 4.5+1.5mm, 6.0+3.0mm, and 8.0+4.0mm, respectively. Since under normal service condition, the major loss of the rubber belt is abrasion, we suggest customers to increase the thickness of rubber cover appropriately at the time of placing order so as to improve the use value of the rubber belt. | |||

Ply bond strength

| Item index | Between plies | Between rubber and carcass | ||

| Thickness of cover ≤1.5 | Thickness of cover >1.5 | |||

| N/mm | N/mm | N/mm | ||

| CC-56 TC-70 | ≥ Average value of longitudinal samples | 3.2 | 2.1 | 2.7 |

| ≥ Min.peak value of longitudinal samples | 2.7 | 1.6 | 2.2 | |

Recommended min. diameter of roller

| Carcass model | Recommended min. diameter of roller for conveyor belt (mm) | ||||||||

| CC-56 TC-70 | 3(plies) | 4(plies) | 5(plies) | 6(plies) | 7(plies) | 8(plies) | 9(plies) | 10(plies) | |

| 400 | 500 | 630 | 800 | 1000 | 1250 | 1250 | 1400 | ||

Contact us if you need more details on Chevron Conveyor Belt. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pattern Conveyor Belt、Cotton Conveyor Belt. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Chevron /Patterned Belt/V-Belt

Premium Related Products

Other Products

Hot Products

Ep300/3 Drive Belt Rubber Conveyor BeltInterlocking Dog Bone Rubber Flooring, Rubber Paving TilesHot Sale! ! Impact Resistant SBR Rubber Sheet with Fabric InsertionLarge Capacity Chevron Rubber Conveyor Belt Made in ChinaEp/Nn/Cc Conveyor Belt From FactoryFirst Class Anti-Tear Conveyor BeltsEPDM Foaming Strip for Doors & Windows SealingMine, Stone, Sand Cement Fabric Nylon Nn Ep Cc56 Tc70 Steel Cord Black Rubber Conveyor Belt / Belt ConveyorTransmission Belt of Oil-Resistant Conveyor BeltRubber Belt of Impact-Resistant Conveyor Belt for Large Goods TransportaionConveyor Blet / Non-Stick Conveyor BeltPipe Conveyor Belt for Coal MiningWear-Resistant (Transmission) Chervon BeltHeat-Resistant Conveyor Belt for Gas WorksProfessional Sidewall Rubber Conveyor Belt/ Transmission Rubber Conveyor BeltNylon Rubber Conveyor Belt / Transmission Belt Made in China