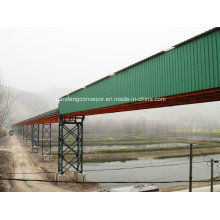

Heavy Duty Industrial Trough Belt Conveyor Material Handling System

Basic Info

Model No.: DTC1000

Product Description

Model NO.: DTC1000 Material: Carbon Steel Application: Chemical Industry, Grain Transport, Mining Transport, Power Plant Usage: Bulk Materials Handling Belt Speed: 1.25-3.15m/S Perfomance Standard: DIN,Cema,ASTM,Sha,etc Conveying Capacity: 17000 Ton/Hr Specification: ISO9001: 2008, Cema, ASTM, DIN HS Code: 84283300 Structure: Conveyor System Material Feature: Oil Resistant, Heat Resistant, Fire Resistant Condition: New Belt Width: 300-2600mm Applications: Mining, Coal Mine, Chemical Engineering, Metallurg Warranty: 12 Months Trademark: Pandeng Origin: Toncheng, China Heavy duty Industrial Trough Belt Conveyor Material Handling System

Features:

1.It's a kind of main conveying equipment that uses ordinary plain faced conveying belt to conveyr bulk materials at large inclination.

2. can conveyor various kinds of bulk material and itemized goods with bulk density of 0.5~2.5t/m³

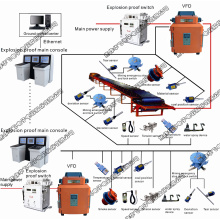

3. Max. Inclination angle of 28°

4.It can greatly decrease the mining capacity on gate road,thus saving a large amount of capital construction investment and accelerating the project progress for gate rod exploitation.

5. It can be used between -20ºC~+40ºC working environment, temperature of conveying material under 80ºC with high adaptability.

6.It adopts the Conveyor Belt made of special materials, which can convey special materials such as high temperature resistant material, acid&alkali resistant material, oil resistant material etc.

7.The belt conveyor can meet the safety requirements for special applications like coal mines etc.

8.It can meet the requirements for explosion protection in coal mines and ensure safe and reliable operation.

9.It's equipped with rigorous monitoring and sensor systems and reliablesafety devices, which can prevent the occurrence of serious acceidents such as runaway,marvering,etc.

Application:

Mining, coal mine, Chemical engineering, metallurgy, harbor, wharf, construction industry etc.

Principle:

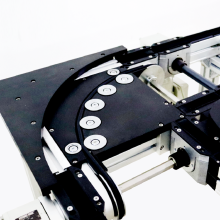

Belt conveyor is composed by frame, belt, roller, tensioning device, transmission device, etc. The frame adopts high quality steel for connection, a certain angle inclined plane is formed because of the different heights of front and rear legs. The machine frame is fixed by belt roller and carrying roller which are used to drive and support the conveying belt. There are two driving ways: geared motor driving and electric

Main technical parameters:

DTII model

DTC Model

Packing Detail:

1.Water-proof nylon wrapping package

2.Steel frame box

3. As request

Our service:

1. Design and select suiable equipment

2. Layout draw, foundation draw and detail equipment manual. Timely report your production schedule and photos for keeping monitoring.

3. Shipping

4. After-service, can dispatch engineer to the site to guide the installation, commissioning, operation etc if client need.

Certificate: ISO9001:2008, BV Contact us if you need more details on Bulk Material Handling. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Steel Plant Conveing、Conveyor Equipment. If these products fail to match your need, please contact us and we would like to provide relevant information.

Features:

1.It's a kind of main conveying equipment that uses ordinary plain faced conveying belt to conveyr bulk materials at large inclination.

2. can conveyor various kinds of bulk material and itemized goods with bulk density of 0.5~2.5t/m³

3. Max. Inclination angle of 28°

4.It can greatly decrease the mining capacity on gate road,thus saving a large amount of capital construction investment and accelerating the project progress for gate rod exploitation.

5. It can be used between -20ºC~+40ºC working environment, temperature of conveying material under 80ºC with high adaptability.

6.It adopts the Conveyor Belt made of special materials, which can convey special materials such as high temperature resistant material, acid&alkali resistant material, oil resistant material etc.

7.The belt conveyor can meet the safety requirements for special applications like coal mines etc.

8.It can meet the requirements for explosion protection in coal mines and ensure safe and reliable operation.

9.It's equipped with rigorous monitoring and sensor systems and reliablesafety devices, which can prevent the occurrence of serious acceidents such as runaway,marvering,etc.

Application:

Mining, coal mine, Chemical engineering, metallurgy, harbor, wharf, construction industry etc.

Principle:

Belt conveyor is composed by frame, belt, roller, tensioning device, transmission device, etc. The frame adopts high quality steel for connection, a certain angle inclined plane is formed because of the different heights of front and rear legs. The machine frame is fixed by belt roller and carrying roller which are used to drive and support the conveying belt. There are two driving ways: geared motor driving and electric

Main technical parameters:

DTII model

| Belt speed m/s | Belt width B (mm) | ||||||||||

| 500 | 650 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 | |

| Conveying capacity Q (t/h) | |||||||||||

| 0.80 | 69 | 127 | 198 | 324 | - | - | - | - | - | - | - |

| 1.00 | 87 | 159 | 248 | 405 | 593 | 825 | - | - | - | - | - |

| 1.25 | 108 | 198 | 310 | 507 | 742 | 1032 | - | - | - | - | - |

| 1.60 | 139 | 254 | 397 | 649 | 951 | 1321 | - | - | - | - | - |

| 2.00 | 174 | 318 | 496 | 811 | 1188 | 1652 | 2186 | 2795 | 3470 | - | - |

| 2.50 | 217 | 397 | 620 | 1014 | 1486 | 2065 | 2733 | 3494 | 4338 | - | - |

| 3.15 | - | - | 871 | 1278 | 1872 | 2602 | 3444 | 4403 | 5466 | 6843 | 8289 |

| 4.00 | - | - | - | 1622 | 2377 | 3304 | 4373 | 5591 | 6941 | 8690 | 10526 |

| 4.50 | - | - | - | - | 2674 | 3718 | 4920 | 6291 | 7808 | 9776 | 11842 |

| 5.00 | - | - | - | - | 2971 | 4130 | 5466 | 6989 | 8676 | 10863 | 13158 |

| 5.60 | - | - | - | - | - | - | 6122 | 7829 | 9717 | 12166 | 14737 |

| 6.50 | - | - | - | - | - | - | - | 9083 | 11277 | 14120 | 17104 |

DTC Model

| No. | New model | Conveying Capacity (t/h) | Belt width (mm) | Belt speed (m/s) | Max. conveying length(m) | Inclination angle (0) | Main motor power (kW) | Drive roller diameter (mm) | Idler diameter (mm) | Original (old) model |

| 1 | DTC80/6/40S | 60 | 800 | 1.25 | 200 | 18~23 | 37 | φ630 | φ89 | |

| 2 | DTC80/13/200S | 130 | 800 | 1.6 | 600 | 16~26.5 | 200 | φ1000 | φ89 | |

| 3 | DTC80/15/250S | 150 | 800 | 2.0 | 780 | 25~8 | 250 | φ1000 | φ89 | |

| 4 | DTC80/18/220S | 180 | 800 | 2.0 | 530 | 25 | 220 | φ1000 | φ89 | SQD-220 |

| 5 | DTC80/18/160S | 180 | 800 | 2.0 | 450 | 22 | 160 | φ1000 | φ89 | |

| 6 | DTC80/25/250S | 250 | 800 | 2.0 | 450 | 25 | 250 | φ1000 | φ108 | SQD-250 |

| 7 | DTC80/30/2×220S | 300 | 800 | 2.0 | 670 | 25 | 2×220 | φ1000 | φ89 | SQD-440 |

| 8 | DTC80/30/250S | 300 | 800 | 2.0 | 500 | 23 | 250 | φ1000 | φ89 | |

| 9 | DTC80/30/2×250S | 300 | 800 | 2.5 | 350 | 25 | 2×250 | φ1000 | φ89 | |

| 10 | DTC80/26/315S | 260 | 800 | 2.0 | 860 | 25 | 315 | φ1250 | φ108 | |

| 11 | DTC100/40/250S | 400 | 1000 | 2.0 | 380 | 23 | 250 | φ1000 | φ108 | |

| 12 | DTC100/40/280S | 400 | 1000 | 2.0 | 350 | 25 | 280 | φ1400 | φ108 | |

| 13 | DTC100/40/355S | 400 | 1000 | 2.0 | 500 | 25 | 355 | φ1000 | φ108 | |

| 14 | DTC100/50/2×250S | 500 | 1000 | 3.15 | 510 | 20 | 2×250 | φ1000 | φ133 | SQD-500 |

| 15 | DTC120/70/2×355S | 700 | 1200 | 2.5 | 655 | 21.5 | 2×355 | φ1250 | φ133 | |

| 16 | DTC120/50/2×400S | 500 | 1200 | 3.15 | 750 | 24 | 2×400 | φ1250 | φ133 | |

| 17 | DTC140/80/2×355S | 800 | 1400 | 2.5 | 240 | 23 | 2×355 | φ1000 | φ133 |

Packing Detail:

1.Water-proof nylon wrapping package

2.Steel frame box

3. As request

Our service:

1. Design and select suiable equipment

2. Layout draw, foundation draw and detail equipment manual. Timely report your production schedule and photos for keeping monitoring.

3. Shipping

4. After-service, can dispatch engineer to the site to guide the installation, commissioning, operation etc if client need.

Certificate: ISO9001:2008, BV Contact us if you need more details on Bulk Material Handling. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Steel Plant Conveing、Conveyor Equipment. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Conveyor Series > Belt Conveyor

Premium Related Products

Other Products

Hot Products

Ep300/3 Drive Belt Rubber Conveyor BeltInterlocking Dog Bone Rubber Flooring, Rubber Paving TilesHot Sale! ! Impact Resistant SBR Rubber Sheet with Fabric InsertionLarge Capacity Chevron Rubber Conveyor Belt Made in ChinaEp/Nn/Cc Conveyor Belt From FactoryFirst Class Anti-Tear Conveyor BeltsEPDM Foaming Strip for Doors & Windows SealingMine, Stone, Sand Cement Fabric Nylon Nn Ep Cc56 Tc70 Steel Cord Black Rubber Conveyor Belt / Belt ConveyorTransmission Belt of Oil-Resistant Conveyor BeltRubber Belt of Impact-Resistant Conveyor Belt for Large Goods TransportaionConveyor Blet / Non-Stick Conveyor BeltPipe Conveyor Belt for Coal MiningWear-Resistant (Transmission) Chervon BeltHeat-Resistant Conveyor Belt for Gas WorksProfessional Sidewall Rubber Conveyor Belt/ Transmission Rubber Conveyor BeltNylon Rubber Conveyor Belt / Transmission Belt Made in China